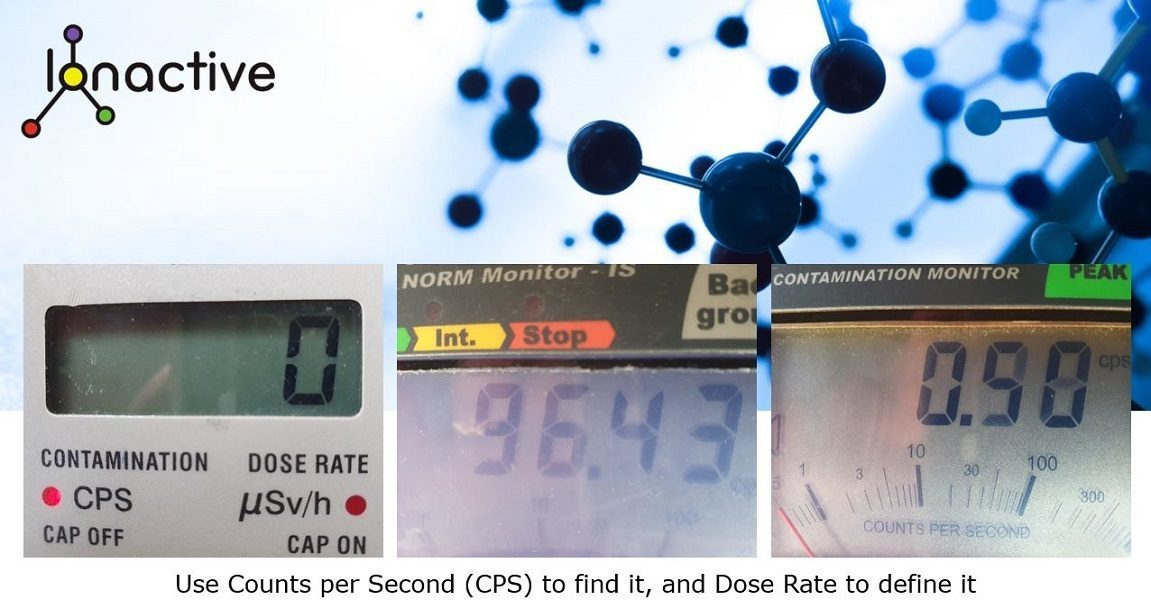

Use Counts per Second (CPS) to find it, and Dose Rate to define it

Published: Sep 29, 2021

This rule of thumb is about monitoring technique and its application needs caution. Its based on the tendency for radiation monitor manufacturers to label their monitors with a ‘function’. Examples include ‘contamination monitor’, ‘NORM monitor’, ‘x-ray monitor’.

Aside from specialist applications, radiation monitoring equipment will generally display one of two types of scale – either rate in CPS (counts per second), or dose rate / exposure in micro Sv/h (or other related units such as mR/h in the US). CPS is often linked with contamination, such that you will find some CPS monitors labelled as ‘contamination monitor’.

For this rule of thumb, we will not consider the monitor technology (geiger muller, scintillation, solid state, ion chamber etc) in detail. Such consideration is important, but will unnecessarily complicate the concept we are discussing here. Consider the rule of thumb as applied to monitoring for x-ray leakage (i.e. a potential shielding fault) in a cabinet x-ray system (something like an airport security x-ray unit).

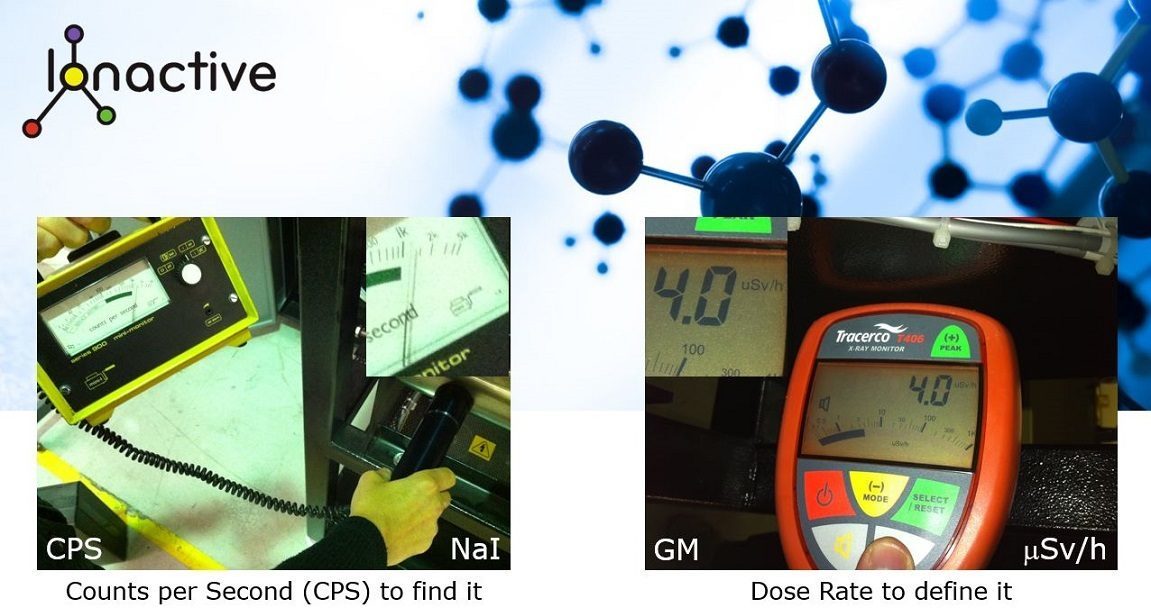

Use Counts per Second (CPS) to find it, and Dose Rate to define it

If you intend to find leakage (a hot spot), you are better off using a CPS scaled monitor. It will generally be more sensitive, and the scale (analogue or digital) will have a larger dynamic range. Background may hover around 1-10 CPS (depending on monitor type) whereas a leak might boost this into the several 10’s of CPS. Overall, this approach means you can monitor quite swiftly with less risk of missing anything. If hotspots are found then they can be marked up with small pieces of sticky tape, removable white marker pen or similar.

Then you can move over to the ‘define it’ principle. How significant is the enhanced count rate (CPS)? This is where you use the dose rate monitor to measure potential exposure in micro Sv/h. [If you are not familiar with the x-ray equipment being checked you might want to measure the dose rate of the first ‘hotspot’ you find to ‘calibrate’ (in your head at least) how CPS relates to micro Sv/h. You can then finish using the CPS monitor before returning to check the dose rate of any hot spots].

You may find you use a ‘contamination’ monitor (as labelled) to measure x-rays from a x-ray generator, so be prepared for some funny looks or questions! Overall, your survey will be more efficient, quicker and you are less likely to miss something.

This technique will work well with x-ray and gamma ray sources. It can be used to measure the extent and direction of 'sky-shine' over open topped shielding bunkers, scatter through shielding ducts, gaps around doors and similar. It is not suitable for all monitoring situations (e.g. alpha or low energy beta sources, surface contamination and similar).

But what about monitoring technology type?

This can now be considered briefly since the rule of thumb has been clearly stated. Monitor technology is of course important and monitor choice considerations would be based on both scale type and detection method.

In the above example we would probably choose a CPS scaled monitor based on NaI detectors with a photo-multiplier tube. These tend to be highly sensitive to x-rays (particularly in the energy range expected from x-ray security equipment). They are quick to react and can be used to ‘scan’ for hotspots, often by just using their audio signal (if you have used one near an x-ray machine they tend to ‘scream’ so do consider who else might be around). The have a large dynamic range so will indicate a relatively high count rate for a modest dose rate above background.

For dose rate we might use a pressurised ion chamber as these give a reliable exposure measurement (e.g. micro Sv/h). Some will suggest an ion chamber is not so good if the ‘leak area’ is significantly less than the area / volume of the ion chamber detector. Whilst this might be true in certain circumstances, using the ion chamber is often a good indicator of ‘real world’ exposure. If you have an x-ray leakage area the size of a 5p coin, then it is not possible for a person to receive a whole-body exposure. If you need a precision dose rate measurement from the hotspot then a tissue equivalent GM based monitor may be more suitable.

Overall, it is useful to remember that a radiation monitor does not know what it is. If it is labelled as a ‘contamination monitor’ (scaled in CPS) this does not mean its only suitable for measuring radioactive contamination on a surface.

What have we not considered?

This rule of thumb has been confined to the use of CPS or dose rate scaled detectors in certain monitoring applications. We have not considered the following matters which are also important:

- The most suitable type of detector technology (a least not in any real detail).

- How far from the surface should the monitoring take place?

- The monitoring pattern to minimise missing anything (important for 100% surveys).

- The speed of monitoring (transit velocity, generally < 10 cm/second).

- Where you should monitor (everywhere, or only where persons have reasonable access)?

- Do you need to monitor beyond any removal shielding panels?

- Are you taking instantaneous dose rate measurements, or do you need to report time averaged measurements?

- Do you need a scattering object in the primary x-ray beam?