IRR17 (17) - Designation of controlled or supervised areas

Published: Sep 29, 2021

Schedule 4 of IRR17 details the matters for mandatory consultation with a Radiation Protection Adviser (RPA). The role of the RPA is considered in IRR17 - Regulation 14 (Radiation protection adviser). The designation of controlled and supervised areas is one of the matters requiring mandatory consultation.

Controlled Areas

Following a suitable risk assessment (IRR17 - Regulations 8), the employer needs to designate an area under their control as a Controlled Area, where the following apply:

- it is necessary for a person who enters the area to follow special procedures designed to restrict exposure, or prevent or limit a radiation accident; or

- the exposure of an employee is likely to exceed 6mSv whole body dose a year, or 15mSv to the lens of the eye, or three-tenths of any relevant dose limit in Schedule 3 of IRR17 (for employees aged 18 and over).

Special procedures in the above paragraph refer to more than ‘generic safety procedures’ which would ordinarily be applied in the area regardless (i.e. simple good safety practice). These procedures must be specifically designed for the purpose of radiation protection.

Likely to exceed means during routine work and during any reasonably foreseeable radiation accident. For many employers designation is based on the potential for a reasonably foreseeable accident, rather than expected annual occupational exposures for routine work. Other employers designate on the basis of the safety systems and checks required, prior to and during exit from, an area where high radiation exposures are imminent. Examples of this would be the 'search and lock-up' of an industrial radiography enclosure prior to exposing a radioactive source, or exiting a radiotherapy room ('last person out button') prior to treating a patient. In these circumstances, it is common to be aware of visual (active signage) and audible alarm signals to warn all persons that radiation exposure is imminent (or the the radiation system is being prepared to emit radiation).

With respect to numerical limits, IRR17 does not go further than the above criteria. The IRR17 ACoP does include additional criteria for controlled area designation which are where:

- the external dose rate exceeds 7.5 micro Sv/h when averaged over a working day. It should be noted that designation is still required when the dose rate is less than 7.5micro Sv/h, but where special procedures are required to meet IRR17 (9)

- the hands of an employee can enter an area and the 8-hour time average dose rate exceeds 75 micro Sv per hour

- there is a significant risk of spreading radioactive contamination outside the working area (the RPA can advise on significant risk)

- it is necessary to prevent (or closely supervise access to the area by employees who are not directly connected to the radiation work (relevant to the industrial radiography and radiotherapy examples provided above )

- employees are liable to work in the area for a period sufficient to receive an effective dose of 6mSv / year (legally correct but a rare reason to designate these days)

- employees untrained in radiation protection are likely to enter that area where the dose rate exceeds 7.5 micro Sv/h (averaged over one minute)

- where the dose rate is less than 7.5 micro Sv/h when averaged over a working day, but the instantaneous dose rate at any point exceeds 100 micro Sv/h

- where industrial site radiography is taking place where the dose rate exceeds 7.5 micro Sv/h when averaged over one minute.

The bullet point 'where the dose rate is less than 7.5 micro Sv/h when averaged over a working day, but the instantaneous dose rate at any point exceeds 100 micro Sv/h' could be inverted to read (with some caution) 'no controlled area required where instantaneous dose rate (IDR) exceeds 7.5 micro Sv/h, where the dose rate averaged over a working day is < 7.5 micro Sv / h, as long as the IDR dose rate does not exceed 100 micro Sv/h'. The use of this derived definition, keeping in mind all the bullet points above, could be useful for shielding justification of radiotherapy bunkers (and similar facilities), where the IDR might clearly exceed 7.5 micro Sv/h (for a small moment in time), but where time averaging analysis shows that the micro-Sv-in-any-one-hour is substantially less than 7.5 micro Sv.

For a UK facility using this type of analysis, the micro-Sv-in-any-one-hour will generally less than 0.15 micro Sv where persons untrained in radiation protection have access, such as public areas. 0.15 micro-Sv-in-any-one-hour is equivalent to 6 micro Sv/week, and 300 micro Sv/year, using standard working hours data - this being a recognised constraint below the 1mSv effective whole body annual dose limit applied to other persons (e.g. members of the public and other persons not involved with work using ionising radiation).

The bullet 'employees untrained in radiation protection are likely to enter that area where the dose rate exceeds 7.5 micro Sv/h (averaged over one minute)' is not particularly helpful and we would recommend you talk to your RPA if you believe this effects your radiation work. This point, derived from the IRR17 ACoP, somewhat conflicts with other areas of this regulation. In addition, it applies to employees but apparently not members of the public (who would not be trained in radiation protection anyway). Our analysis of micro-Sv-in-any-one-hour is far more sensible and we would debate this point with the UK regulators.

Do not over-designate, or designate for the wrong reasons

The need to control access will also influence the decision of whether an area needs to be designated. There may be some management arguments for designating a controlled area in order to restrict access for reasons other than simply radiation protection – perhaps to enhance security. However, over designation should be avoided unless the area can meet all the requirements – particularly those in IRR17 - Regulation 19 (Additional requirements for controlled areas).

Designation based on annual expected exposure is best avoided

Caution should be given to designating on the basis of expected annual dose to employees alone. For example, if an area is occupied by an employee for 2000 hours a year (40 week, 5 days per week), then a continuous ambient dose rate of only 3 micro Sv/h would be enough to require designation on the basis that the 6 mSv/ year is reached.

Who is responsible for designating the area as controlled (or supervised)?

The employer in control of the area is responsible for the area's designation. This will be obvious for many fixed systems behind company walls (e.g. research laboratories or industrial irradiators). However, in the medical sector, it is common to formally hand over the area between the hospital and contractors (e.g. installation or service engineers). The test here, among other things, is 'who has the finger on the button which can produce a radiation exposure in the area?'. If a service engineer is working on an x-ray unit and requires it to admit radiation as part of diagnostic checks, then the area usually becomes the controlled area of the engineer's employer (with associated risk assessment, local rules, contingency arrangements, restriction of access etc). Once the work is complete the engineer would hand back the controlled area to the hospital. In the medical sector there is a specific procedure for this handover and hand back, this can be obtained from our downloads section 'Medical controlled area handover procedure'. The principles noted here are of course relevant to other employers with controlled areas outside the medical sector.

What do I need to consider when designating an area as controlled or supervised?

(Supervised areas are considered separately below, however the advice in this section applies in the determination of all designated areas, controlled or supervised).

The following matters should be considered:

(a) who is likely to require access to the area (and who should not require access to the area)

(b) the level of supervision required (including entry and exit procedures, as well as the work which takes place in the area)

(c) the nature of the radiation sources in use and the extent of the work in the area (including sealed or unsealed radioactive sources, and radiation generators)

(d) the likely external dose rates to which anyone can be exposed (IRR17 Regulation 8 - risk assessment - should have this data)

(e) the likely periods of exposure to external radiation (a good understanding of the task, the nature of the source, and occupancy is vital)

(f) the physical control methods already in place, such as permanent shielding and ventilated enclosures (including physical and procedural safety interlocks etc)

(g) the importance of following a procedure closely in order to avoid receiving significant exposure (compare working with unsealed radioactive materials, and a fully shielded table top cabinet x-ray system)

(h) the likelihood of contamination arising and being spread unless strict procedures are closely followed (IRR17 Regulation 8 - risk assessment should consider this)

(i) the need to wear PPE in that area (requires understanding the nature of the source, and weighing up benefits of PPE against other radiation safety principles)

(j) maximum doses estimated for work in the area (useful, but avoid trying to infer annual exposures from limited measurement or assessment).

Are controlled areas fixed once designated?

In some cases, for example a laboratory holding unsealed radioactive material, the area is likely to remain designated for the lifetime of planned work. However, there are certain cases where controlled areas may not be fixed (and this will normally be specified in local rules).

i) There may be circumstances where a work area such as a ward / treatment area in a Nuclear Medicine department can be de-designated at the end of the working day - post monitoring (to prove absence of radioactive contamination). This would then allow cleaners access without needing to consider radiation protection (otherwise they would be working under a written system of work, in the local rules, to allow them access to the controlled area).

ii) Certain medical facilities (e.g. diagnostic x-ray, linear radiotherapy treatment rooms) may have a way of turning off and 'locking off' a system so that inadvertent / unauthorised generation of radiation is not reasonably foreseeable. If this is the case then its usual that active 'controlled area' signage (e.g. illuminated warning signs) are wired into the generator / linac safety circuit so they cease to be illuminated when no radiation generation is possible. Conversely, they will always be illuminated when radiation generation is possible. Note: the ability to de-designate an area when not generating radiation only applies where the generator is shut down / locked off as described. It does not apply to an area where regular entry and exit is require between each period of radiation generation. The reason for this is that special procedures will be required during the day to ensure no person (unless they are a patient in the case of a medical facility) is left in the area prior to radiation being emitted. Furthermore, for some facilities such as large industrial irradiation plants, monitoring prior to entry post shut down is a special procedure likely to require permanent controlled area designation.

Controlled Areas: X-ray enclosures and the Health and Safety Executive (HSE)

X-ray enclosures such as those used for cargo screening (particularly those where entry is possible) are commonly designated as controlled, and for good reason. Special procedures are required to control exposures (e.g. making sure no person is inside the unit prior to generating x-rays, and during the handover and hand back of the area to a service engineer). In respect of the service engineer, they will be using special procedures to restrict exposure, in particular the special checks necessary at the end of the work to ensure that radiation safety critical systems (interlocks, shielding, warning lights etc) are functional.

We have been aware of cases where the HSE have also requested that the user of x-ray equipment in the food and beverage industry have their x-ray enclosures designated as controlled. This includes those enclosures where its difficult to gain entry (other than by hand), where detectors at the entry or exit will cause cessation of x-rays should they detect a hand (instead of expected product for screening), and where dose analysis has shown that exposures to the hand will not lead to ‘controlled area’ levels of exposure. Furthermore, conversations with an HSE inspector for radiation also indicated they expect a fully enclosed x-ray cabinet (i.e. access only via an interlocked door), even where that cabinet is not large enough for person entry, to be designated as ‘controlled’ (but would not expect a controlled area sign).

In the past: In the above cases, local rules, an RPS and a risk assessment would always be present (even though the area might not be formally designated), since IRR17 as a whole still applies. The use of local rules and the appointment of a RPS is then simply good health and safety practice.

Nowadays: It is the view of HSE (in conversation with Ionactive) that special produces are required to gain entry to the food screening unit (e.g. to free a stuck product), and in the case of the fully contained x-ray cabinet, special procedures would be required by a service engineer to ensure the x-ray cabinet was safe following service / maintenance. In these cases, practical radiation safety (and its management via local rules and the RPS) is evident, but clearly there is an expectation that controlled area status is expected. If you already have local rules, RPA and risk assessment (etc) in place, then designating the inside of the x-ray cabinet in the above examples requires minimal additional effort. If in doubt seek advice from your RPA.

Supervised Area

Over the last 20 years or so we have seen very few supervised areas when compared to controlled areas. This may come as a surprise, particularly when you look at average annual exposures across many groups and find them substantially below 1 mSv effective whole body dose. The issue is 'potential' exposure as apposed to expected exposure during routine work. Nevertheless, we think that over designation takes place in many work areas. The formal considerations for designating a supervised, after suitable risk assessment are where:

- it is necessary to keep conditions under review to determine whether the area should be controlled or supervised; or

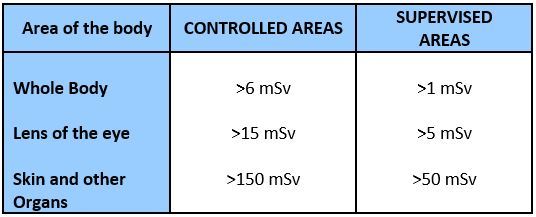

- a person is likely to receive an effective dose greater than 1mSv per year, or an equivalent dose greater than one tenth of any relevant dose limit referred to in Schedule 3 (except in the case of dose to the lens of the eye, where > 5mSv but < 15 mSv would require a supervised area).

The criteria for supervised (and controlled) areas are summarised in the table below.

Typical areas that might be designated as supervised include:

- Laboratories for research using low activity radioactive material. It is common in the university sector to designate a small area of a larger laboratory as supervised, for the purposes of controlling radiation exposure in that area and ensuring records are maintained and disposals are made down designated sinks.

- Research 'hot labs' where higher activity radioactive materials are dispensed or processed - it is common to designate the laboratory as supervised and the fume cupboard as controlled.

- Change areas (where lab coats / gowns / overshoes are worn or taken off) are often supervised. This area might also be used for hand washing and personal monitoring with a hand or foot monitor. The area acts as a 'buffer zone' between non-designated areas outside and the controlled area beyond the changing room.

If you need advice regarding any of the matters in this section, please consider a formal consultation with an Ionactive RPA (see Radiation Protection Adviser services).