RPA Life – Explaining a problem you don’t have

Published: Feb 16, 2019

A radiation protection blog post from Mark Ramsay, Radiation Protection Adviser (RPA) for Ionactive Consulting Limited.

Early years

I started my radiation safety career back in 1990. My first proper job was working with Amersham International (now GE) at their White Lion Road site in Amersham, Buckinghamshire. I did not really know what I was letting myself in for, I was appointed as an Environmental Surveyor (radiation monitor) and it was my job to go around and monitor things for radiation and radioactive contamination. It soon became apparent to me that this was important, if not ‘dangerous work’, since whenever there was maintenance or other engineering jobs, we were always front of line checking if the area was ‘safe’ first. I felt quite important to be honest (my importance was not reflected by my pay grade of the time!).

After a couple of years at Amerham, I decided to go to University (I had had not wanted to do this directly after leaving school). During my time at Nottingham University, my peers and university lecturers and technicians used to ask me about my previous work experience and were genuinely interested in my ‘risky job’ working with nuclear materials and radioactive sources.

Following university, I went to work at AWE (Atomic Weapons Establishment). As a graduate trainee I got to see everything (and I mean ‘everything’) - it was a fascinating job. During this time I studied for a NEBOSH Diploma in occupational safety and health, and an MSc in Radiation & Environmental Protection. Whilst the MSc met my physics geek needs, it was the safety qualification that opened my eyes to all the other occupational hazards around. Bit by bit I was noticing the slips, trips and falls and all the while provide a radiation safety role as part of the training scheme.

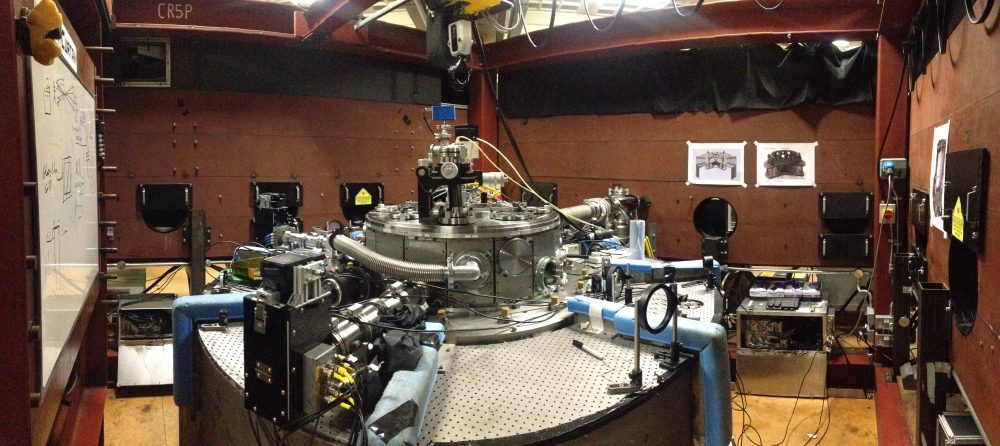

I will spare you more words on the intervening years between then (above), and now (Ionactive Consulting), other than to say I had extensive periods of rewarding work, the longest being RPA to Imperial College London for 10 years. Imperial was fascinating and where else in the UK can you mix up analytical laboratories, actinide chemical engineering delay tanks, the MAGPIE (Mega Ampere Generator for Plasma Implosion Experiments) and a nuclear research reactor (CONSORT). This lot kept my feet firmly in radiation safety, but I was ever more conscious of the more conventional hazards (electric shock, manual handling of shielding materials, falling from height etc).

So… on to explain the problem you don’t have.

Radiation risks in the workplace

There is a legal requirement to have a Radiation Protection Adviser appointed for most ionising radiation work in the UK. There are very few safety-related legal appointments (Radioactive Waste Adviser and Dangerous Goods Safety Adviser come to mind). You do not legally need to appoint a Safety Adviser or Safety Officer (of course these are essential roles for occupational safety and health in the workplace). The simple fact you ‘appoint’ the RPA in writing appears to elevate the perceived radiation risks you have in the workplace. When I visit a new client workplace to assess their work with ionising radiation, I am not just evaluating radiation risk, I am measuring that risk against all the other conventional hazards in the workplace. I am no expert in conventional safety, and I will not provide official advice, but I might direct my client in the direction of an expert if I feel that is the right thing to do.

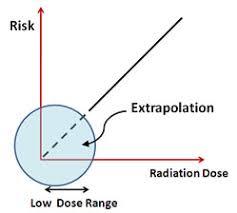

With some exceptions (I will provide an example in a moment), there are very few uses of ionising radiation in the workplace that will do you measurable, clinically observable harm. I do not want to get too bogged down in radiation risk, and all the controversy over Linear No-Threshold models (LNT) – for my day job I really need to go with accepted standards and the law. In this regard, the annual dose limit for an occupationally exposed worker is 20mSv/year (whole body effective dose). Broadly speaking (and after some simplification), 20mSv has an excess fatal cancer risk of 1:1000 (statistically originating from ionising radiation exposure). This can be compared to perhaps 1:4 cancer deaths in the population from all causes (environmental factors, diet, chemicals, radon gas, alcohol, bad luck etc). Now, using LNT, one can ‘predict’ that the excess cancer risk of 1mSv (delivered over a year, the dose rate is irrelevant) is of the order of 1:20,000. To put this into context (and a lot of this is still subjective and open to interpretation), a 1:1000 fatal risk might be realised from the highest risk industries (perhaps coal mining?), whereas 1:100,000 fatal risk might be realised from an accident in some of the safest workplaces (office?). So you can see where 1mSv fits in…..

But it does not end there. Ionactive has clients working with industrial sterilisers, high activity sealed sources (HASS), linear accelerators, reactor decommissioning, quality assurance, security x-ray machines and more. Many of these could be considered high hazard (significant sources of radiation), but low risk (low probability of exposure). However, in the above cases using risk assessments (that consider occupational exposure from routine work and reasonably foreseeable accidents), our typical predictions range from no measurable exposure above background (background is about 3000 micro Sv/year averaged over the UK), through to perhaps 10 micro Sv/year, or maybe up to 100 micro Sv/year). Yes, exposures to most clients are that low. [We do have certain clients with individuals working in sectors where occupational exposures are up to 5mSv a year or a little higher still. In addition, being inside a Co-60 industrial sterilisation plant with all the sources exposed will kill you in seconds, you will worry little about cancer.]

Let me take 10 micro Sv / year estimate as a good average (and note this can be applied to those working with industrial sterilisation plants containing >> 3.7 x 1016 becquerels, or >1MCi in old money of Co-60). That is, using LNT, about an excess fatal cancer risk of 1:2,000,000. In some ways I suggest you ignore the statistics (!), just compare 10 micro Sv/year to background radiation.

Some statistics

According to HSE statistics, 144 workers were killed in the UK during the RIDDOR 2017/2018 period. Using the same statistics, the rate of fatal injury at work is about 1:200,000 over a year (this rate has been about the same each year from 2012 onwards). My peers in radiation risk (especially those who think LNT is a load of rubbish) will not thank me for comparing this to fatal cancer risks from occupational radiation exposure. But I will. It’s about 100 micro Sv.

So, there IS a drive under current radiation safety legislation (based on ICRP 103 recommendations) to ensure that exposures are ALARP (as low as reasonably practicable below dose limits). My own ‘constraint’ for clients is < 1mSv / year (and >99% of them achieve better than this by orders of magnitude, many approaching background levels). But not at the expense of other areas of more conventional health and safety.

Explaining the problem they don't have

When I visit a client and look at their freight forwarding x-ray machine, I take a good look around. Whilst I examine their x-ray shielding curtains, I observe the folk lift truck movements and safe walkways. Whilst I monitor the radiation dose rate levels in working positions, I might observe how they are stacking pallets on top of each other. Whilst I look at their radiation safety documentation I might just glance across the room and observe the fire escape.

I am not perfect either (far from it). The other day I was working for a client who occupies a massive manufacturing site. Its heavy industry with cutting machines, noise, heavy lifting with cranes and heat etc. I was walking down some stairs with a radiation monitor in one hand and a clipboard in the other. I was about to take some dose rate measurements around their industrial radiography bay. I ignored the safety signs on the stairs ‘Notice: use handrail’. I got told off. I smiled inwardly and thought – ‘no doubt this site has a risk register populated in the correct order ’. I also felt pleased that I had reassured the site that all was well with their radiation protection, all was compliant. I advised them about the problem they didn’t have, and let them get on with dealing with risk reductions in other areas of occupational safety and health.